- About Ability

- Product & Services

- Core Competencies

- CareersLife at ABILITY

- Investor Relations

- ESG

- Support

The industrial revolution provided us with physical superpowers in manufacturing, which increased the efficiency and agility of manufacturing processes. Ability is confident in maintaining consistent high product quality for our current customers whiling attracting new customers from industry leaders.

From standardization to automation and AI, we seamlessly integrate systems with streamlined workflows for high-efficiency and zero-defect production.

Able to adapt quickly to diverse customer needs with our agile production systems, ensuring timely and quality of delivery.

By leveraging Overall Equipment Effectiveness (OEE) and Machine-to-Machine (M2M) communication, we maximize equipment efficiency and streamline production lines for optimal performance.

Maintain top-notch product quality with comprehensive Statistical Process Control (SPC), Shop Floor Control (SFC), and Product Lifecycle Management (PLM) systems.

Streamline operations with the Warehouse Management System (WMS) and Enterprise Resource Planning (ERP) integration

Stay ahead with smart demand forecasting, enhance Supply Chain Management (SCM), SAP, Global Supply Manager (GSM), automated robotics, cutting-edge 3D measurement tools, and more.

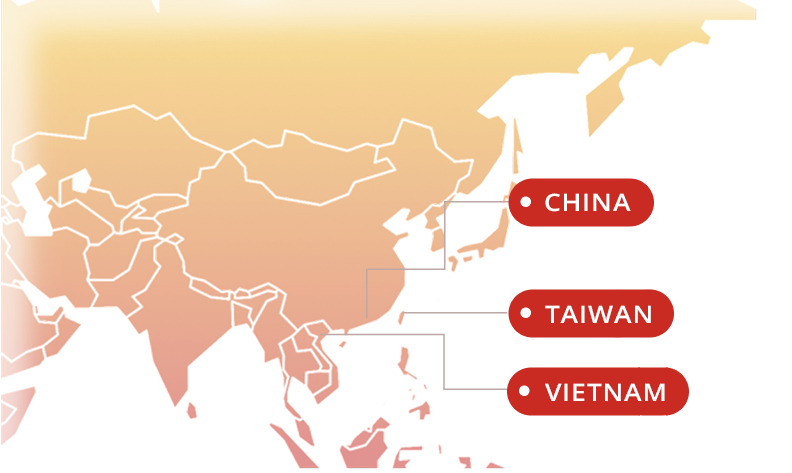

Enhancing Project Success with Flexible Manufacturing Solutions across Taiwan, Vietnam, and China. Leverage Ability Enterprise’s Cross-Regional Strengths for Agile and Scalable Manufacturing.

Ability Enterprise's strategically located manufacturing facilities in Taiwan, Vietnam, and China empower global customers with versatile production solutions tailored for speed, precision, and scale. Each location plays a key role in delivering high-quality EMS and ODM services, from rapid prototyping and NPI (New Product Introduction) to high-volume production and specialized assembly. Our cross-border integration ensures flexible resource allocation, optimized lead times, and supply chain resilience.

With deep experience in optical imaging, smart devices, IoT, and automotive applications, Ability’s regional manufacturing capabilities support diverse industry needs—while maintaining consistent standards of quality and reliability. Partner with Ability to turn complex ideas into market-ready solutions—efficiently and confidently.

Ability Enterprise’s Manufacturing Centers are steadily advancing a three-phase automation strategy—standalone automation → process automation → intelligent logistics—across our production bases in Taiwan, China, and Vietnam. This strategic roadmap supports the implementation of six core smart manufacturing capabilities, enabling a robust, flexible, and highly integrated production ecosystem.

We have implemented a wide range of automation technologies across key production processes, including optical center alignment, focus adjustment, automated screw fastening, adhesive dispensing, and soldering. These are complemented by advanced inspection systems such as image calibration systems, image stitching alignment systems, and other precision testing modules—all designed to improve process consistency and ensure exceptional image quality across products.

Our manufacturing sites are also equipped with intelligent management tools and quality control systems, including integrated firmware flashing and voltage testing platforms, automated functional retest systems, continuity test management software, error-proofed functional testing, and high-temperature burn-in processes. Additional systems, such as oven baking and resting time control, visual inspection tools, Warehouse Management Systems (WMS), and fully integrated Manufacturing Execution Systems (MES) with real-time data reporting, enable end-to-end production transparency and traceability.

With complementary technical strengths and synchronized management, our facilities in Taiwan, China, and Vietnam collaborate to standardize automation practices and continuously optimize workflows. This integrated approach enhances Ability Enterprise’s manufacturing resilience and product reliability, delivering scalable and high-quality ODM solutions for camera modules, automotive cameras, and a wide range of imaging products.

Initial product idea and planning phase

Request for quotation stage with potential partners

Creating detailed product designs

Design for manufacturing to ensure feasibility

Building and testing prototypes

Mass production readiness