- About Ability

- Product & Services

- Core Competencies

- CareersLife at ABILITY

- Investor Relations

- ESG

- Support

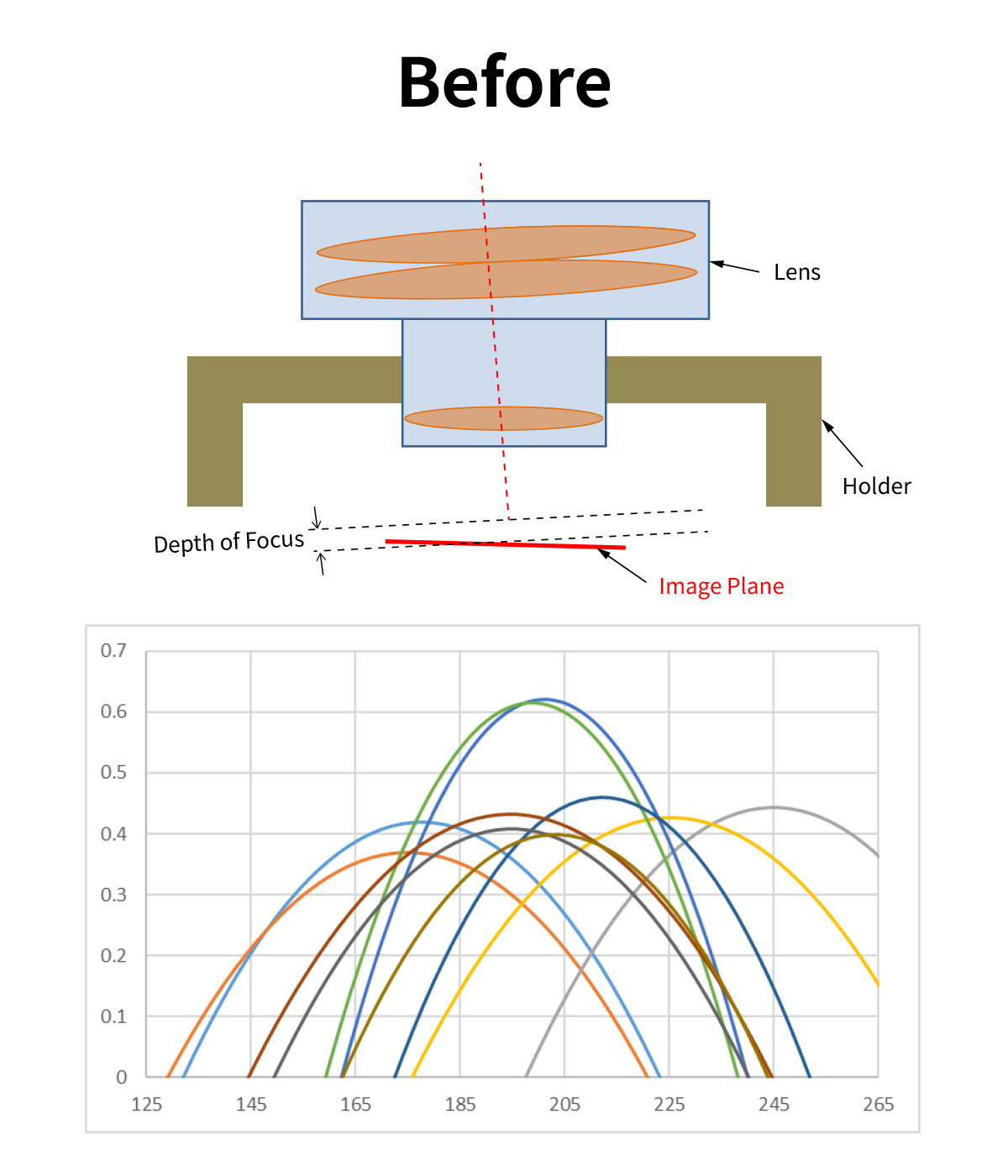

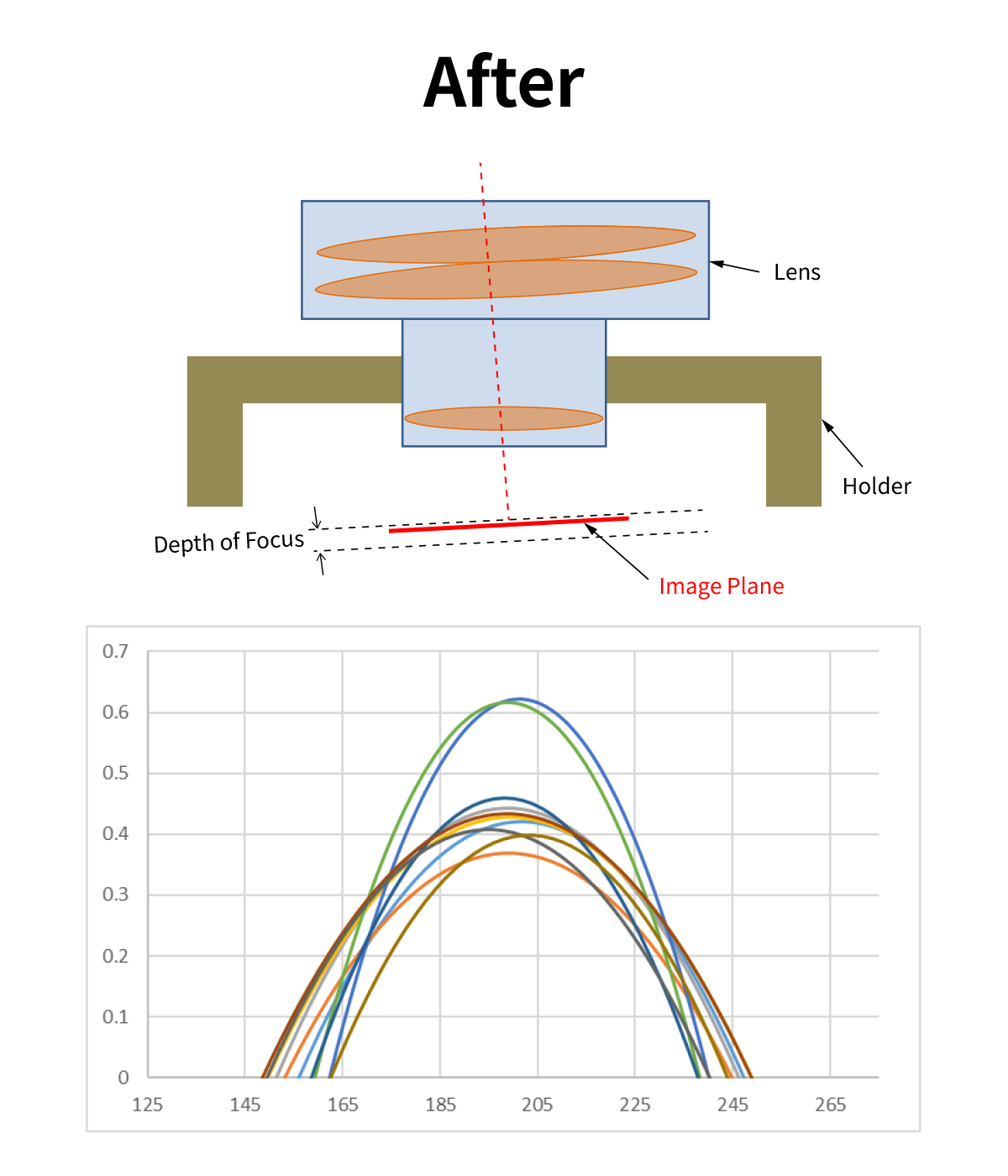

Automated active alignment is a critical process in manufacturing precision lens modules. By precisely controlling the position and angle of each lens within the module, this technology ensures optimal image quality across the entire field of view.

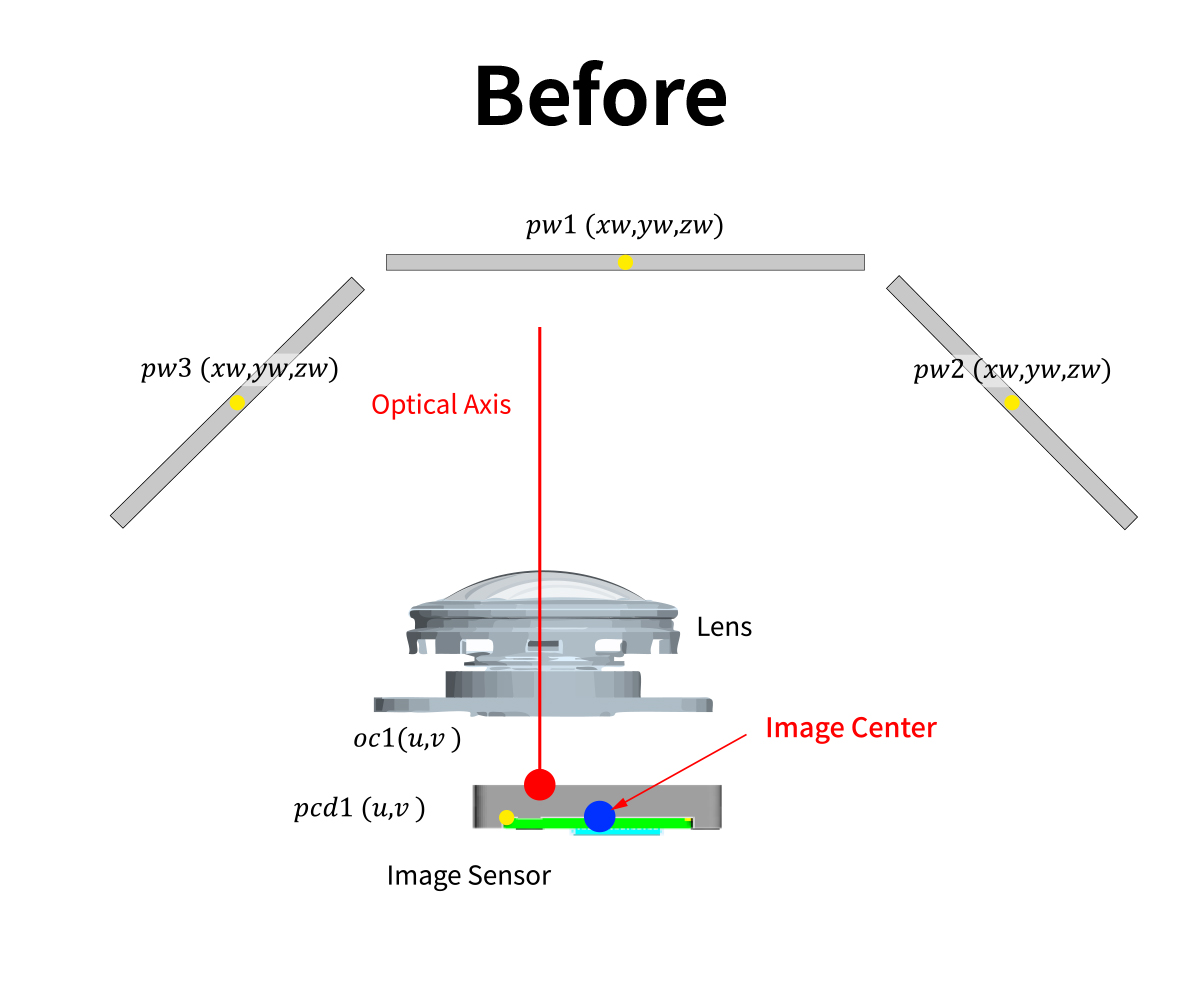

At the heart of our camera system lies advanced software and firmware that handles the intricate task of aligning the sensor and lens. During the auto-alignment process, the firmware conducts precise calculations and makes fine adjustments to the optical center, thus ensures optimal image quality.

The firmware also plays a critical role in post-processing images. By applying distortion correction and optimizing the field of view (FOV), we significantly enhance image quality and minimize distortion. These improvements are made possible by the firmware's precise control of the optical center.

Once the auto-alignment process is complete, our firmware manages and applies the calibration data. This ensures that the alignment adjustments are consistently applied to every captured image, resulting in reliable and consistent image quality.

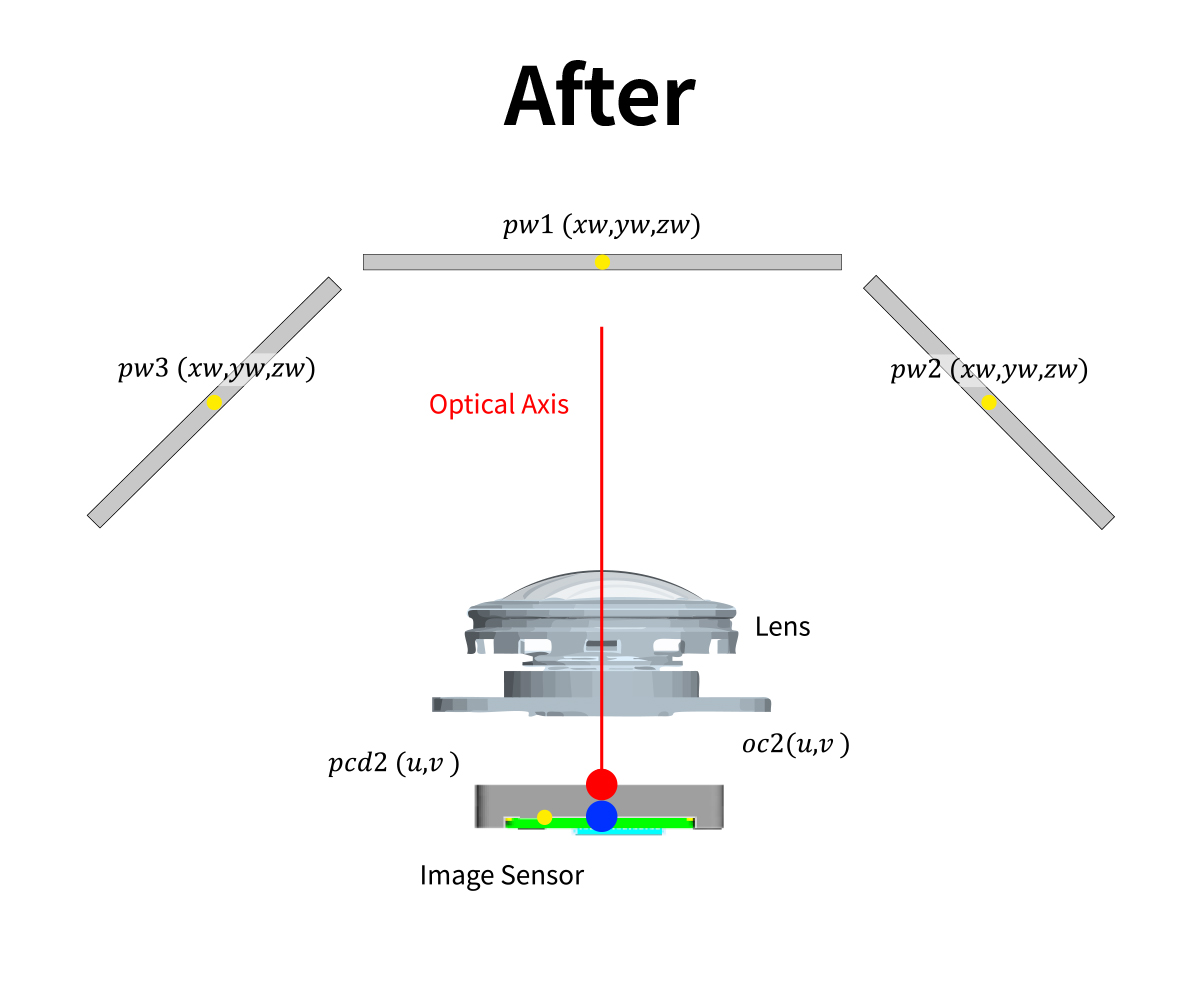

Ability has extensive experience in calibrating ultra-wide-angle fisheye lenses. As illustrated in the image above, our multi-point calibration process guarantees exceptional accuracy and control over image distortion, which leads to unparalleled alignment accuracy with a distortion of less than 5 pixels from the center of the image sensor.

The active alignment process plays a crucial role in maximizing throughput and ensuring consistent image quality across the entire field of view. By having the widest possible margin plane, as illustrated in the image on the right, we can minimize tolerances caused by glue dispensing variations, leading to higher yield.