- About Ability

- Product & Services

- Core Competencies

- CareersLife at ABILITY

- Investor Relations

- ESG

- Support

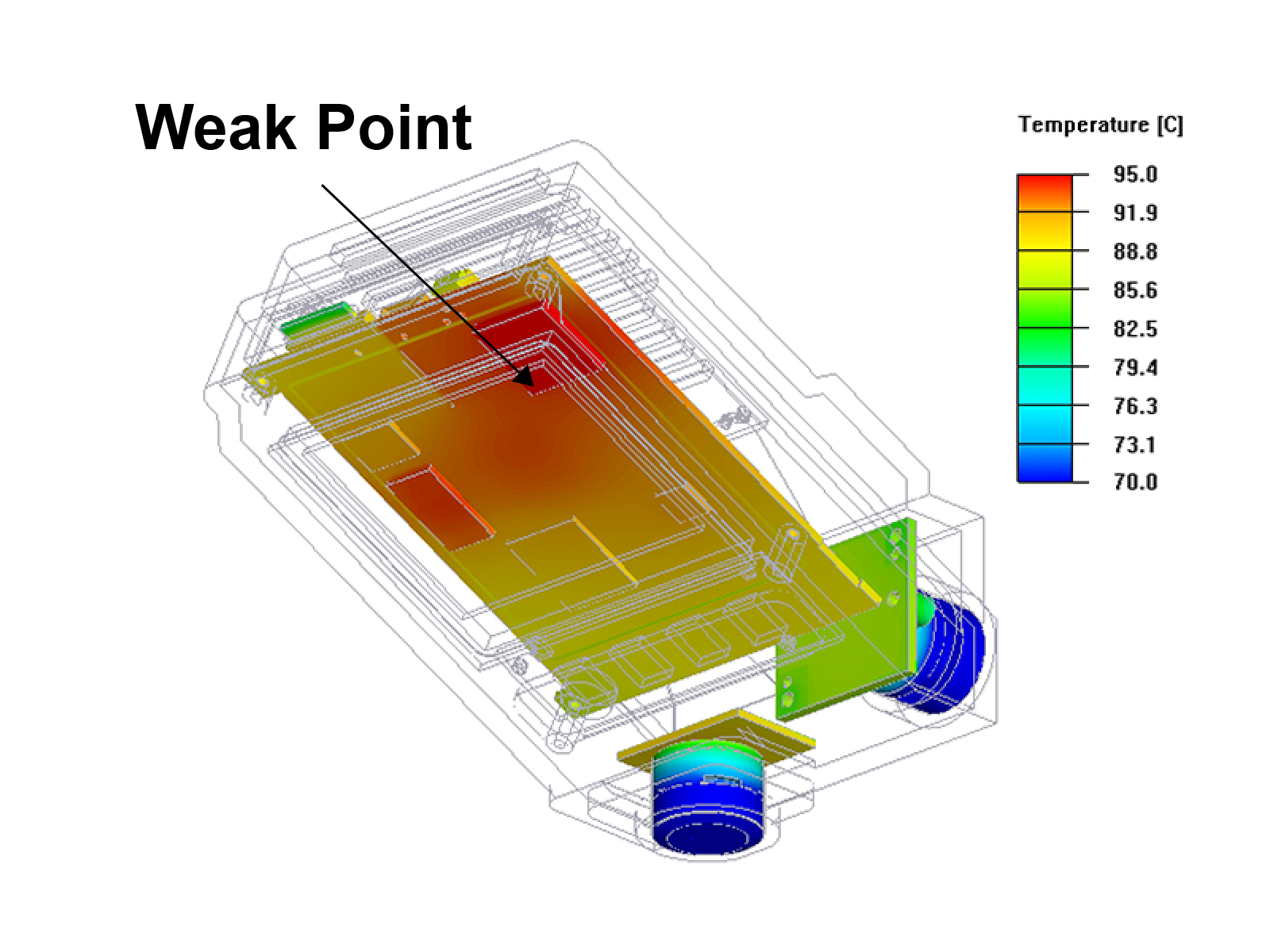

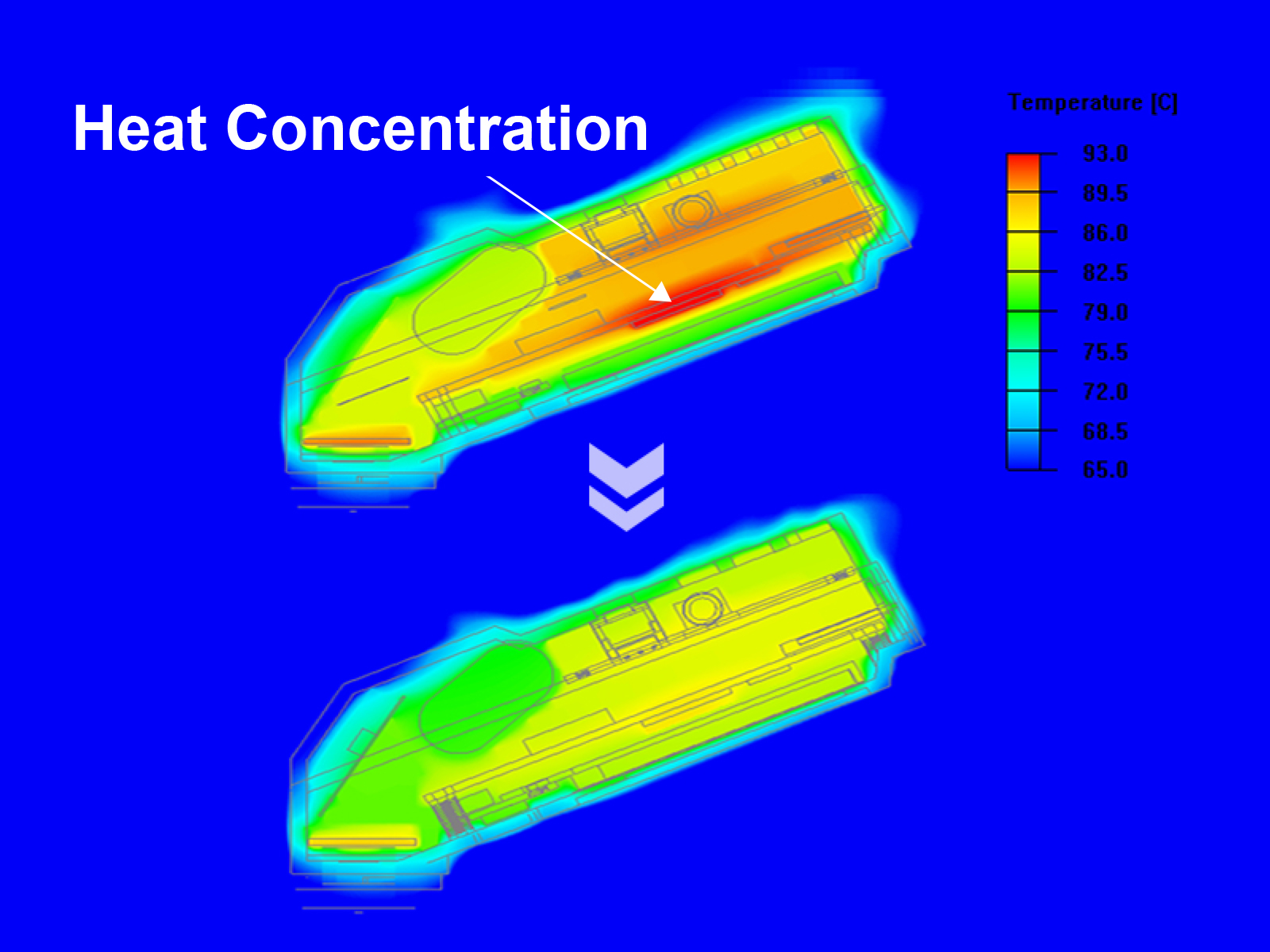

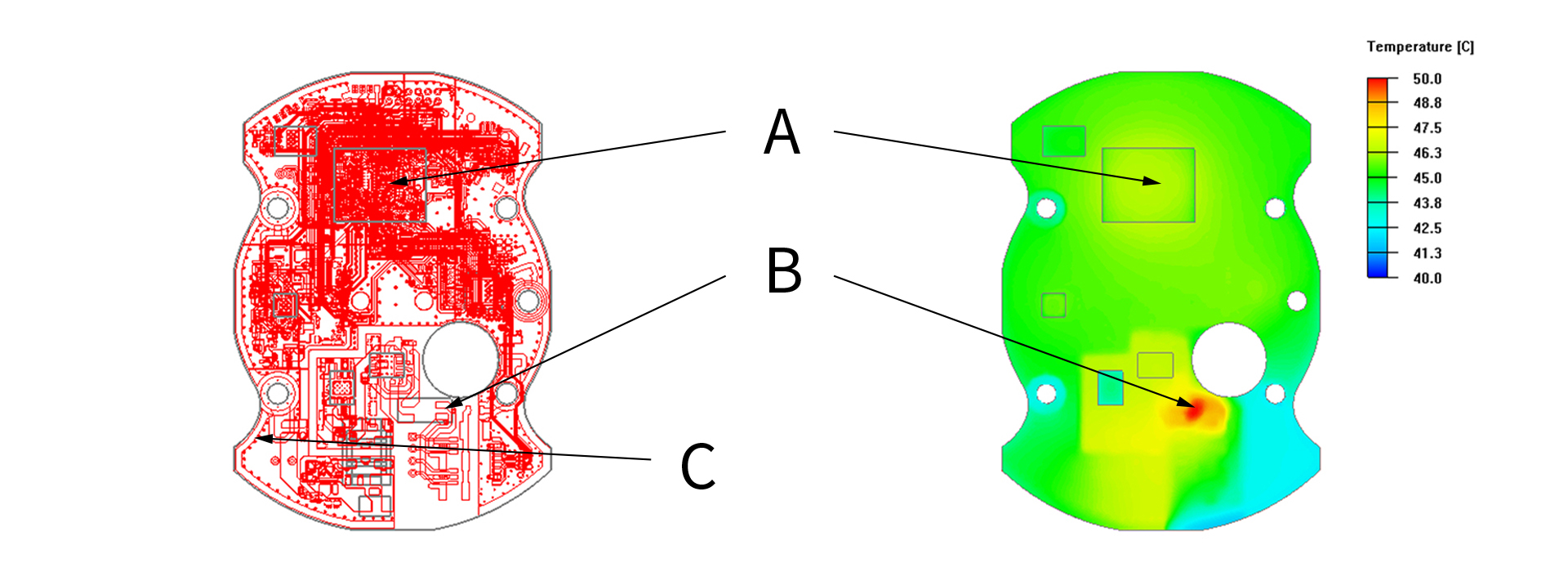

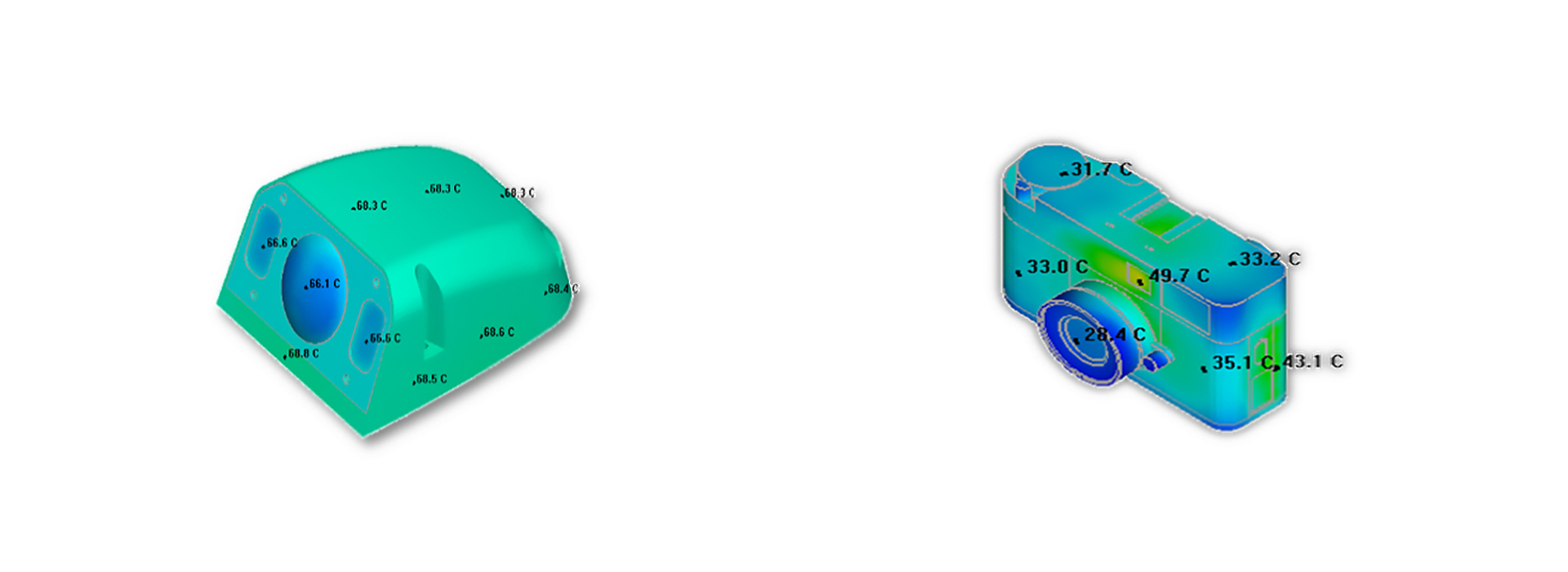

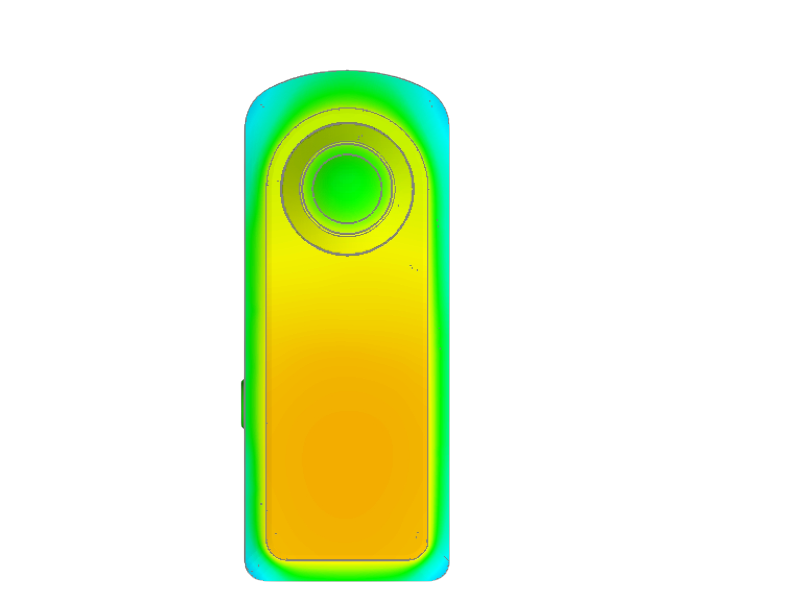

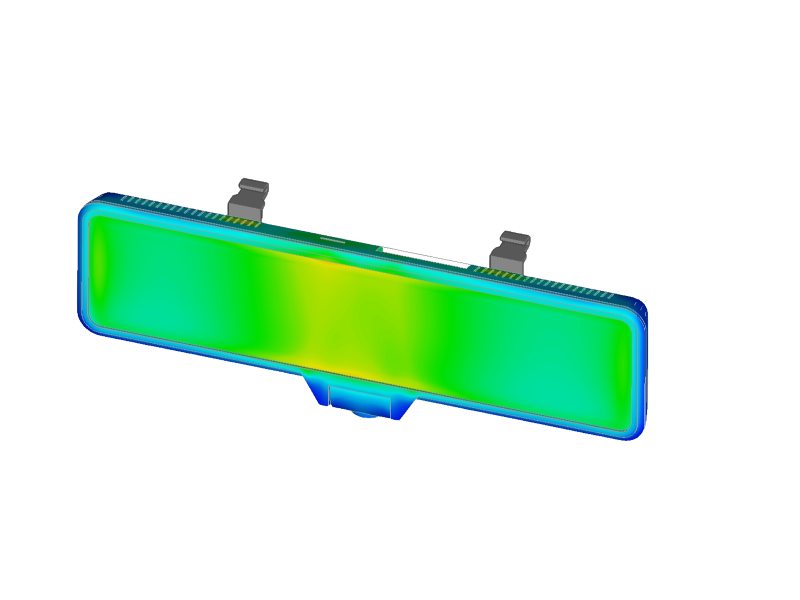

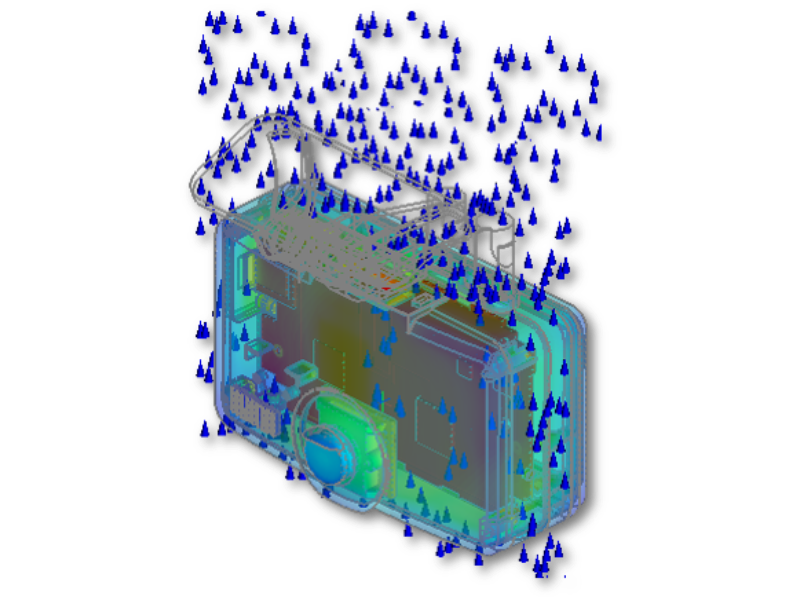

Ability's CAE Thermal Team offers accurate temperature and thermal risk prediction. We specialize in optimizing thermal dissipation efficiency and solutions during the design phase.